China Supplier High Strength Clear Plastic Polycarbonate Corrugated Roofing Sheet

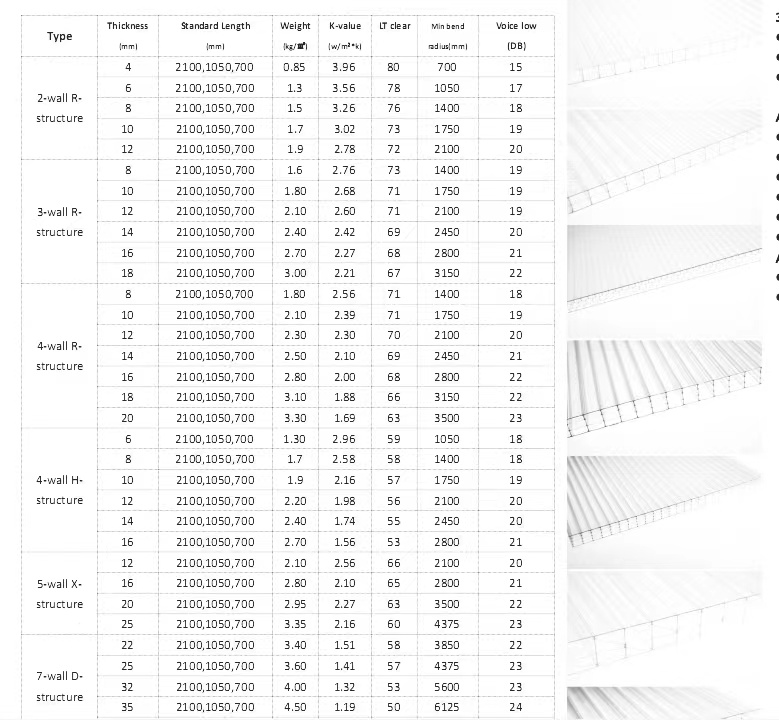

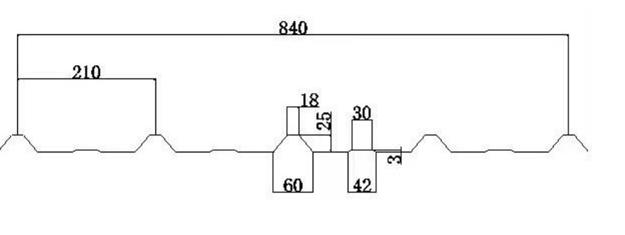

Production Specification:

Corrugated Polycarbonate Sheet

| size | Custom Size and Cut to Size. |

| Thickness | 0.7-3mm |

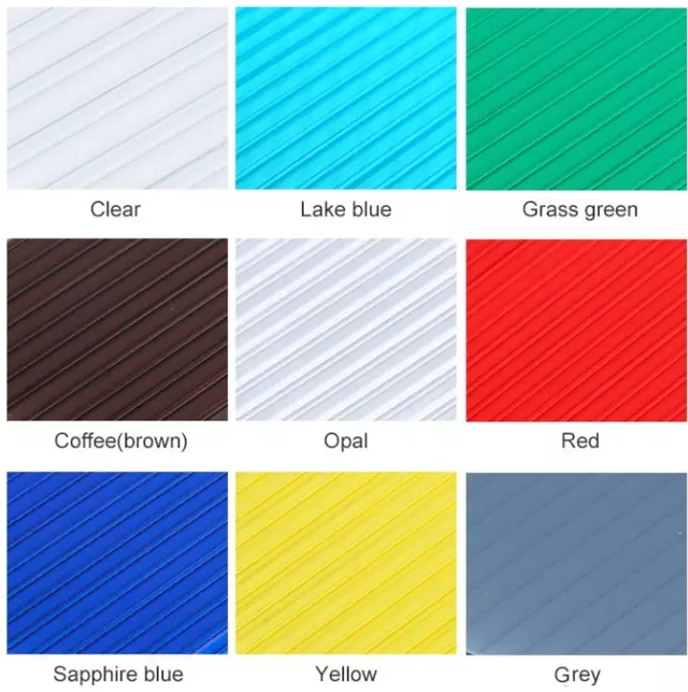

| color | Clear,brown,blue and other different colors |

| Surface | UV protection |

| Samples | Free samples will send to you for test. |

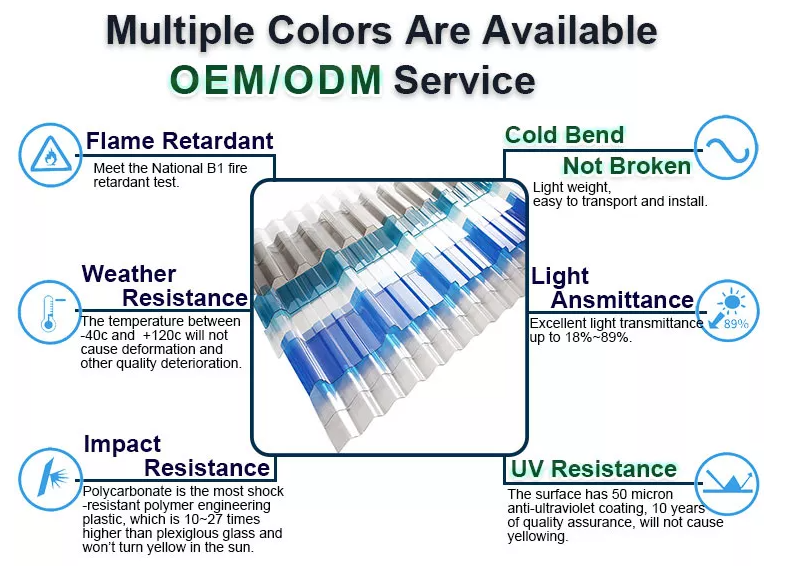

Light transmittance: Light transmittance of 88%, good light transmittance.

Weather resistance: The surface of UV resin can prevent the fatigue of resin caused by UV light. The surface has a good effect on the photosynthesis of the plant by the chemical bond of UV to absorb ultraviolet light and convert to visible light.

Impact resistance: The strength is 10 times of the ordinary glass, is the general wave tile's 3 to 5 times, is the toughened glass's 2 times, does not have the breakage risk.

Flame retardancy: is a flame retardant B1 class, no fire drops, no gas.

Temperature resistance: In the temperature range from 40 DEG C to +120 DEG C, the product will not cause deterioration of the quality such as deformation

Portability: The utility model has the advantages of light weight.

1. Using exquisite craftsmanship and strict inspection standards, make the tinting of polycarbonate sheet more uniform.

2. The normal thickness of anti-UV layer is 50 micron. If for special projects, we can do 100 micron, or even thicker.

3. To prevent pc sheets fade easily and extend service life, we use color master-batch instead of toner.

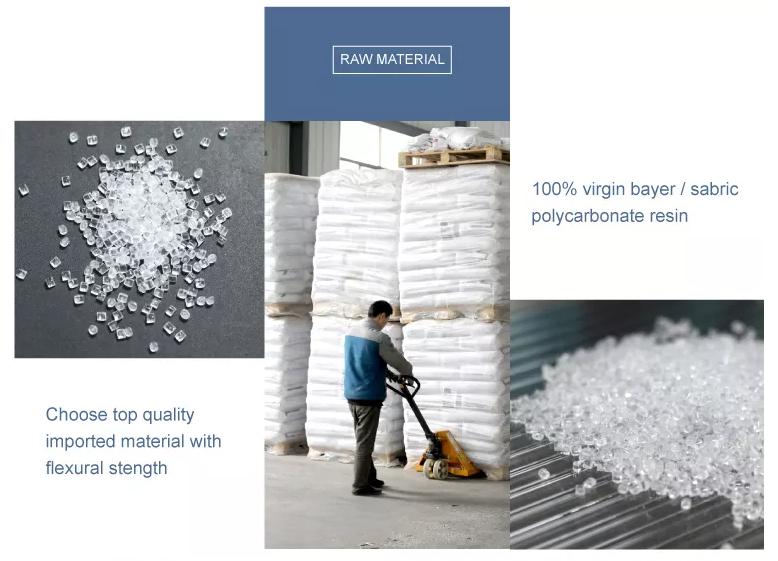

4. For raw material, we all use 100% virgin polycarbonate material. This helps us produce very high quality polycarbonate sheet without defects, and helps us gain good reputation among customers.

Features of polycarbonate sheet:

1. High thermal insulation

2. Light weight and impact resistant

3. High light transmission

4. Weather and UV resistance

5. Easy to handle and install

Color Opinions

Customized colors are available!

Application

Architectural roofing and skylights

Industrial rooflights

Agricultural greenhouses

Residential roofing: Pergola, canopies etc.

Light roofing and awnings

Polycarbonate raw material

Special size and colors can be customized according to requirements!

Q: Who are we?

We are based in Hebei, China, sell to South America,North America,Domestic Market,Mid East,South Asia,Africa,Central America,Southeast Asia,Western Europe,Eastern Asia,Oceania,Southern Europe,Northern Europe,Eastern Europe. There are total more than 200 people in our factory.

Q:What is the payment term?

A:Usually we accept T/T (30% advance and balance against B/L copy), L/C and Escrow. Other payment terms can be negotiable.

Q:What is the delivery time?

A:For normal sheets orders, we can deliver within 10days. For orders that require cut-to-size services and thermoforming, delivery time will be extended.

Q: How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

Q: What can you buy from us?

POLYCARBONATE HOLLOW SHEET,POLYCARBONATE SOLID SHEET,POLYCARBONATE CORRUGATED,POLYCARBONATE U LOCK SHEET,POLYCARBONATE EMBOSSED SHEET, etc.

Q:Why choose us?

A:1. Using 100%imported raw material polycarbonate resin.

2. Advanced UV-PC co-extrusion lines (5 lines).

3. ISO certification.

4. Customized colors and dimensions upon request.

5. Strong capabilities of cutting and thermoforming.

Q:How can become our distributor?

A:We are interested in cooperating with importers of building and decorative materials. Agents worldwide who have good credibility and extensive sales network will be welcomed.

For more information, call 8615230198162 (WhatsApp)

email amanda@stroplast.com.cn

or visit www.kyplasticsheet.com